Introduction

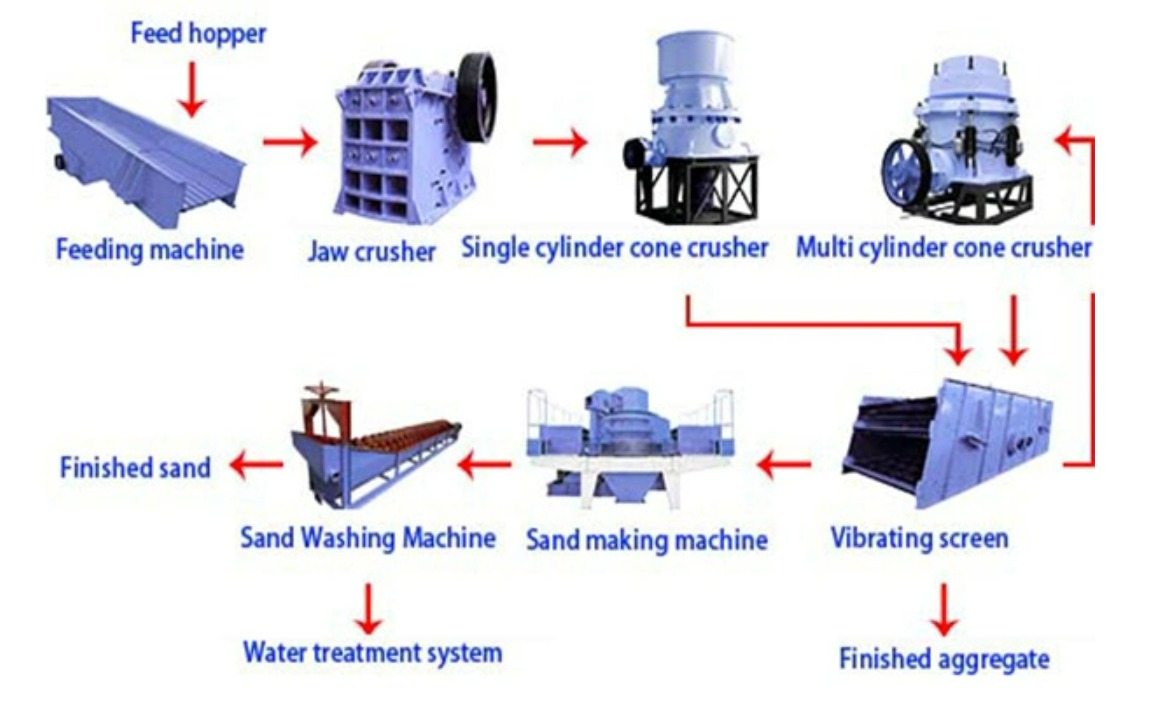

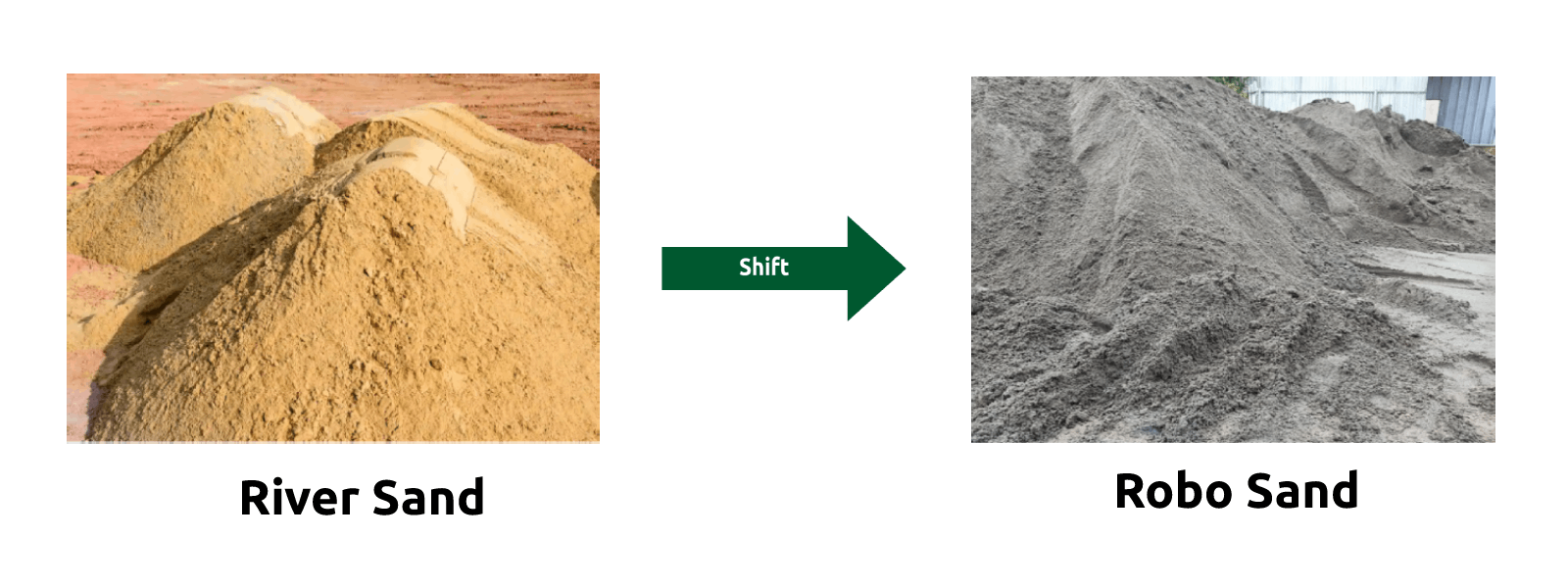

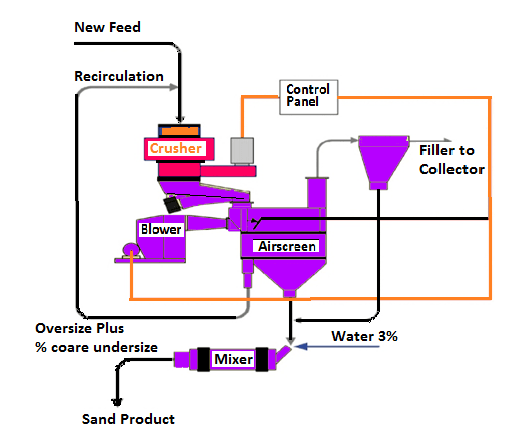

The use of manufactured sand as a replacement for river sand is increasing with the ban on sand mining implemented by different states. The other factors are the general decline in the availability of river sand and pressure from active environmental groups to protect the nature.

Urban Growth

The phenomenal rise in the construction activity in the last decade has contributed to the wide gap between the supply and demand of river sand. A lot of damage has been caused to the eco-systems by carrying out dredging operations on the sand beds leading to the depletion of ground water levels in the country.