x

R

O

B

O

S

I

L

I

C

O

N

-

Call: 1800 103 1789

-

Email: sales.robo@rdc.in

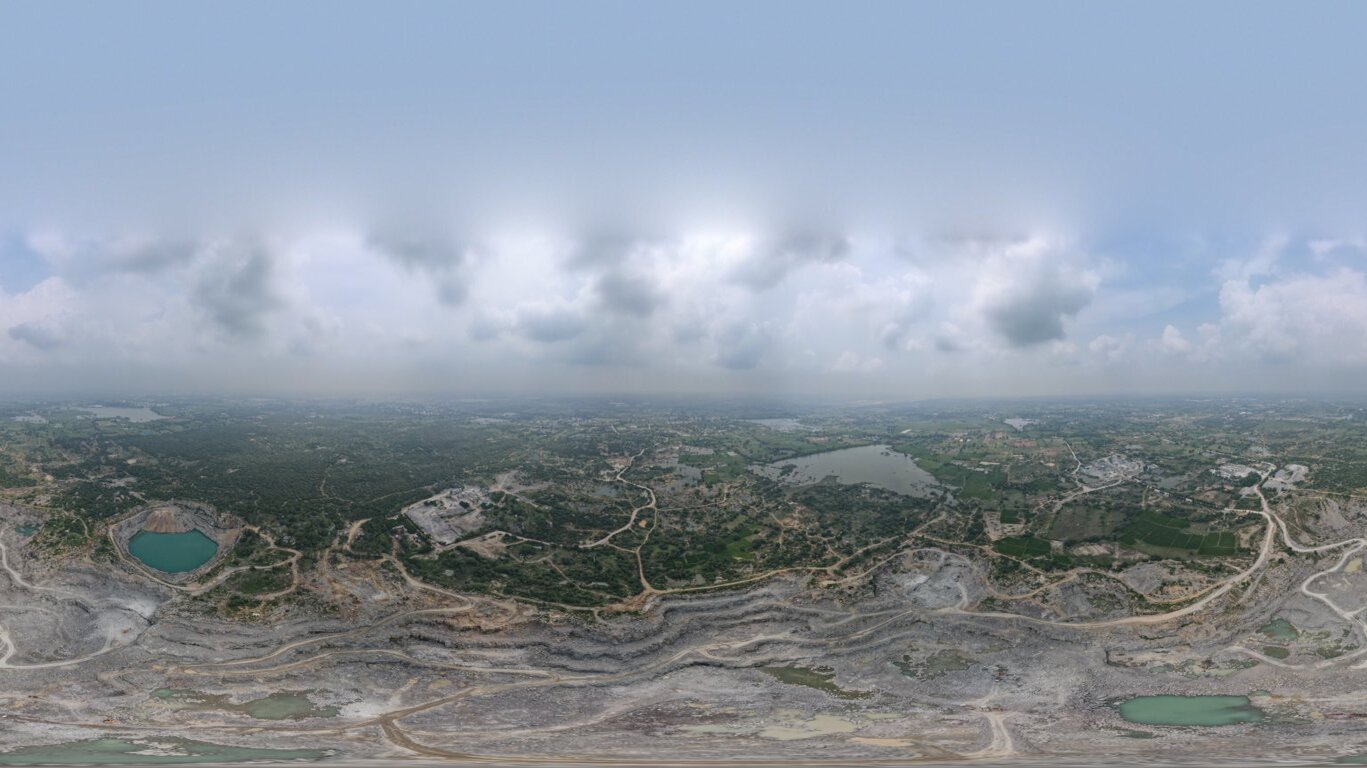

Girmapur-1

- Survey No. 345,

Girmapur Village,

Medchal Mandal

Ranga Reddy District

Telangana

PIN:501401

Girmapur-II

- Survey 248/1,

Bandamadharam Village,

Medchal Mandal,

Ranga Reddy District

Telangana

PIN:501401

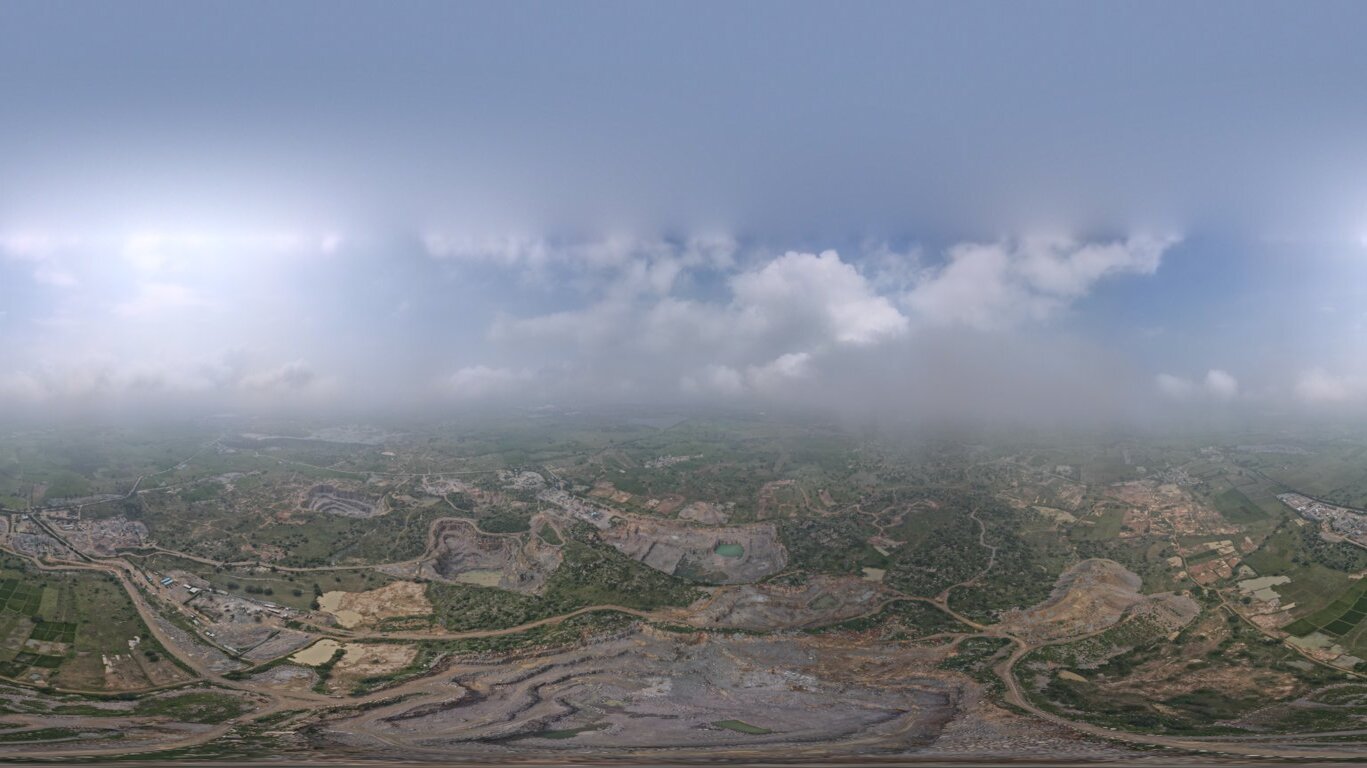

Keesara

- Survey No: 87,

Pedda Parvathapur,Bommala Ramaram,

Yadadri District

Hyderabad

Telangana

PIN:500083

Solakpally

- Survey No. 103, 104 & 105,

Peddakanjarla,

Patancheruv,

Sangareddy,

Telangana

PIN:502319

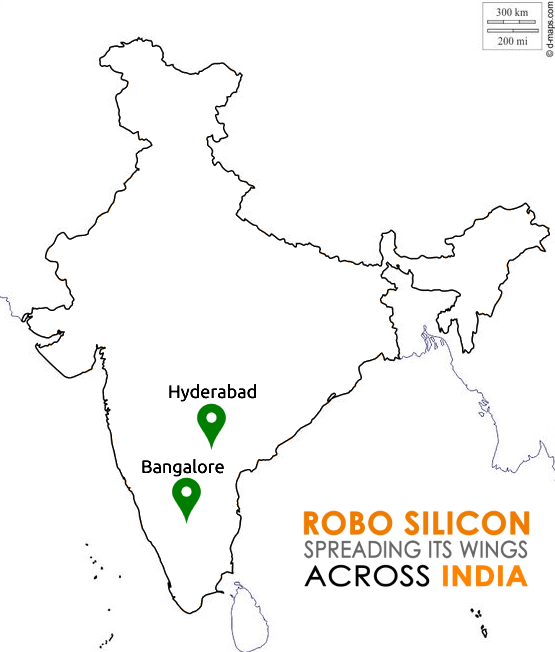

Bangalore

- Survey No. 196, Bidadi,

Bidadi Hobli,

Urgahalli Village,

Bangalore Rural District

Karnataka

Mangalore

- Sy No 22/4A,22/4b,5

Nellikaru Village

Kallamelu House

Mangalore Taluk, Dakshina Kannada Dist

Karnataka

INDIA MAP

Gallery